Introduction:

In the dynamic landscape of modern manufacturing, Artificial Intelligence (AI) has emerged as a game-changer, revolutionizing traditional processes and paving the way for enhanced efficiency, cost savings, and overall operational excellence. This article explores the diverse applications of AI in manufacturing, showcasing its impact on predictive maintenance, inventory management, production planning, and procurement.

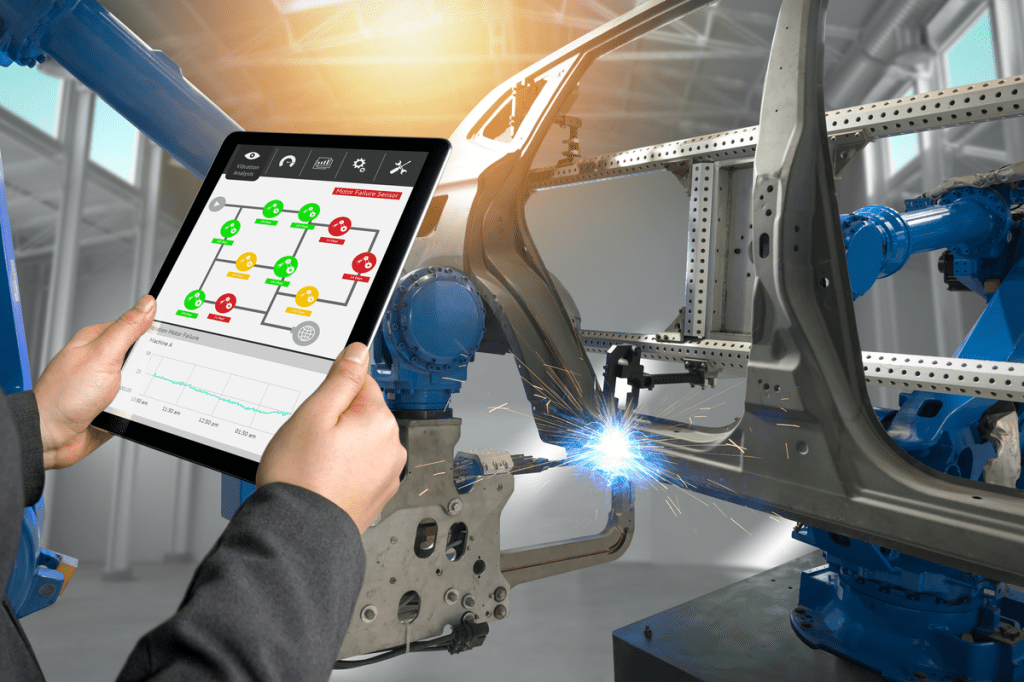

AI in Predictive Maintenance:

Predictive maintenance, powered by AI algorithms, has become a cornerstone of efficient manufacturing. By leveraging machine learning models, manufacturers can predict equipment failures before they occur, reducing downtime and maintenance costs. Sensors embedded in machinery collect real-time data, which is then analyzed to identify patterns indicative of potential issues. This proactive approach enables timely intervention, minimizing disruptions to production schedules.

Case Study: XYZ Automotive Industry

XYZ Automotive Industry implemented an AI in predictive maintenance system that analyzes sensor data from production line machinery. This system accurately predicts equipment failures, allowing the maintenance team to schedule repairs during planned downtime, preventing unexpected breakdowns and optimizing overall equipment effectiveness.

AI in Inventory Management:

Managing inventory efficiently is crucial for manufacturing operations. AI in inventory management helps optimize stock levels, reduce carrying costs, and prevent stockouts. Machine learning algorithms analyze historical data, market trends, and demand forecasts to predict optimal inventory levels. This ensures that raw materials are available when needed, reducing lead times and avoiding production delays.

Case Study: ABC Electronics

ABC Electronics integrated AI into their inventory management system to streamline procurement processes. By analyzing historical data and market trends, the system accurately forecasts demand, allowing ABC Electronics to maintain optimal inventory levels. As a result, they experienced a significant reduction in carrying costs and minimized instances of stockouts.

AI in Production Planning:

Efficient production planning is vital for meeting customer demands while minimizing costs. AI in production planning utilizes advanced algorithms to optimize production schedules, allocate resources efficiently, and reduce waste. Real-time data analysis allows manufacturers to adapt to changing demand patterns and optimize production lines for maximum output.

Case Study: LMN Pharmaceuticals

LMN Pharmaceuticals implemented AI-driven production planning to optimize their pharmaceutical manufacturing processes. The system dynamically adjusts production schedules based on real-time demand fluctuations and resource availability. As a result, LMN Pharmaceuticals achieved a notable increase in production efficiency, reducing lead times and enhancing overall customer satisfaction.

AI in Procurement:

AI is transforming the procurement process by automating routine tasks, improving decision-making, and enhancing supplier relationships. Machine learning algorithms analyze supplier performance, market conditions, and historical data to identify cost-saving opportunities and mitigate risks. This data-driven approach allows manufacturers to make informed procurement decisions, negotiate favorable terms, and maintain a resilient supply chain.

Case Study: PQR Manufacturing Solutions

PQR Manufacturing Solutions adopted AI in procurement to enhance supplier relationship management. The system evaluates supplier performance metrics, such as delivery times and quality, to identify top-performing suppliers. This data-driven approach has empowered PQR Manufacturing Solutions to negotiate favorable terms, reduce procurement costs, and ensure a reliable supply chain.

Conclusion:

The integration of AI into manufacturing operations is reshaping the industry, driving efficiency, and enabling organizations to stay competitive in the global market. From predictive maintenance to procurement, AI applications are providing manufacturers with valuable insights, optimizing processes, and ultimately contributing to enhanced productivity and profitability. As the manufacturing landscape continues to evolve, embracing AI technologies will be essential for companies aiming to achieve and sustain excellence in their operations.